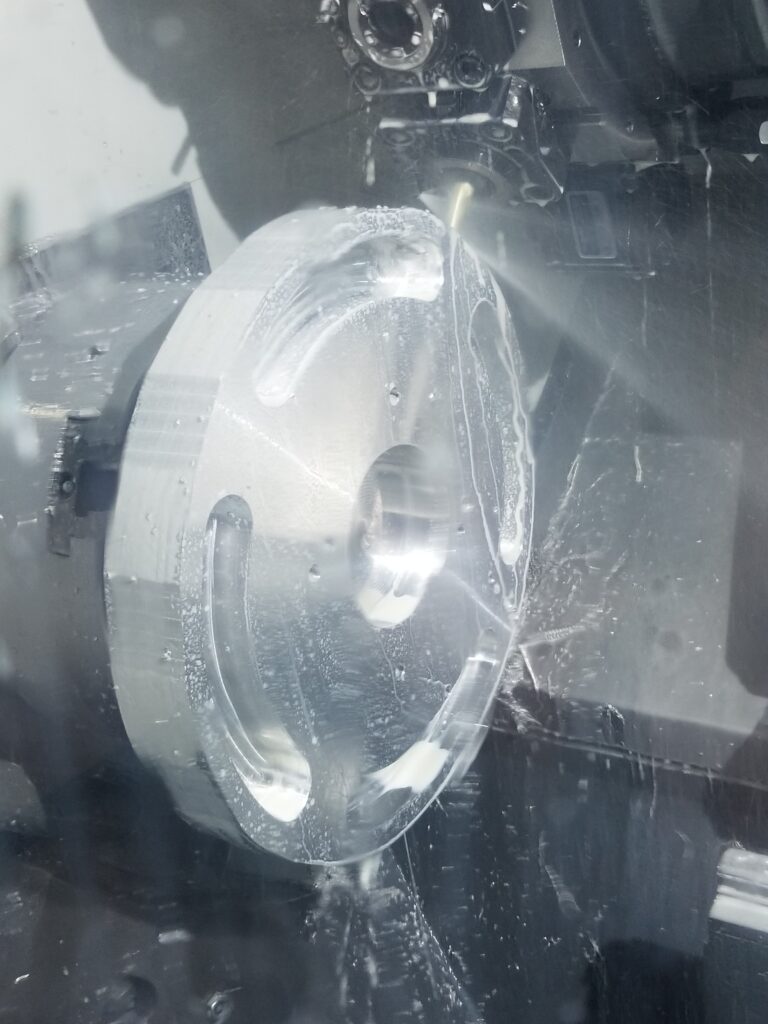

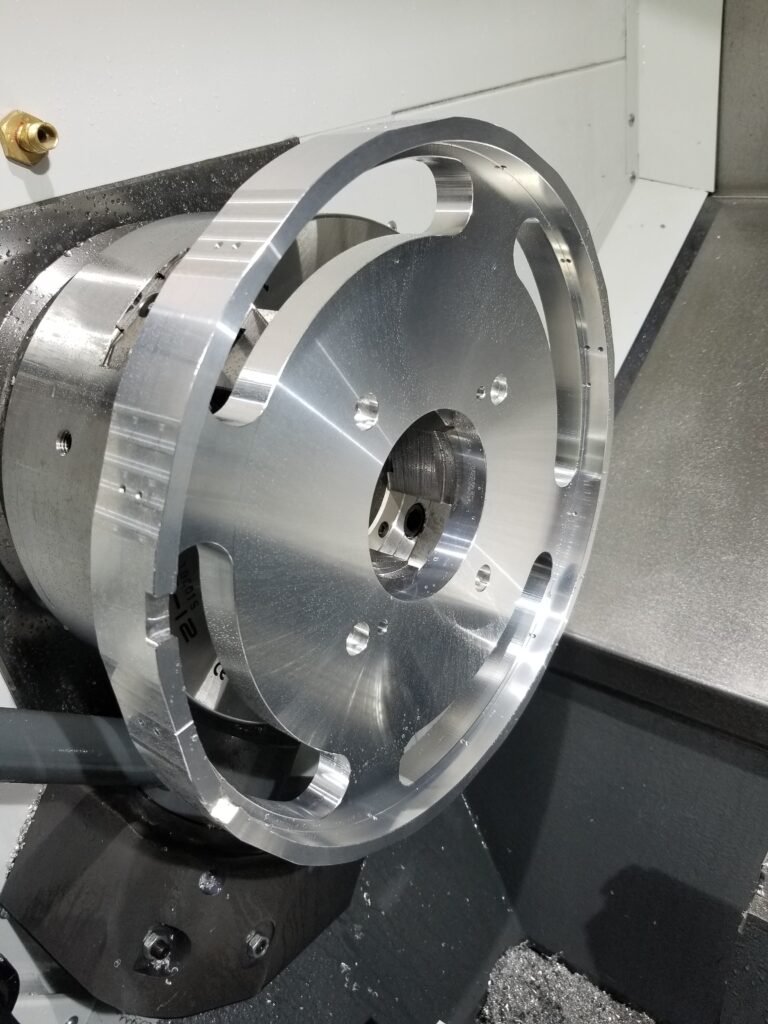

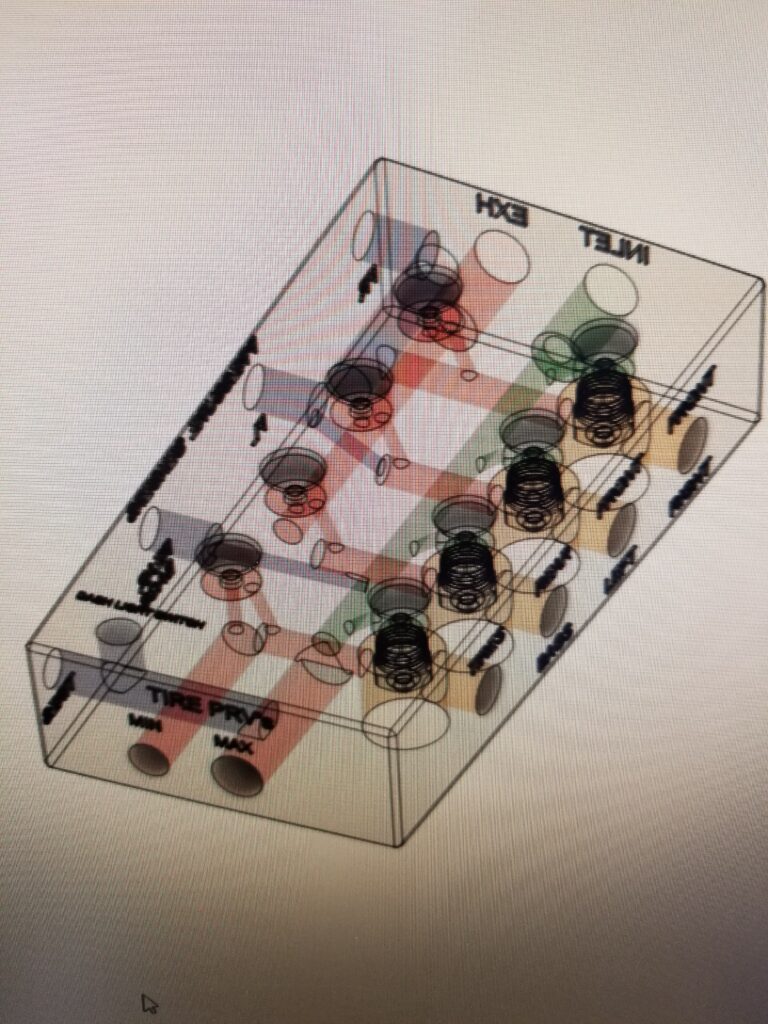

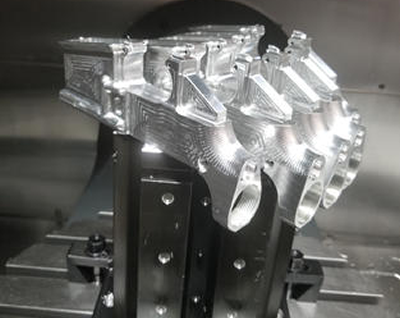

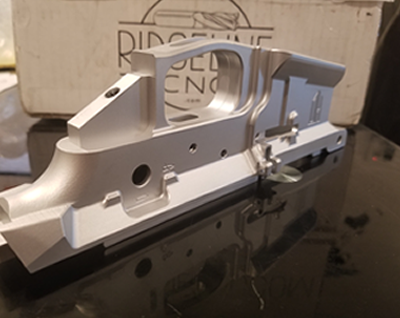

PRECISION PARTS FOR

YOUR AUTOMATION LINE

Working with the top industrial automation manufacturers and specialists in the country, provides us with a unique advantage in crafting superior parts and important pieces to keep your lines running safely and securely 24/7.