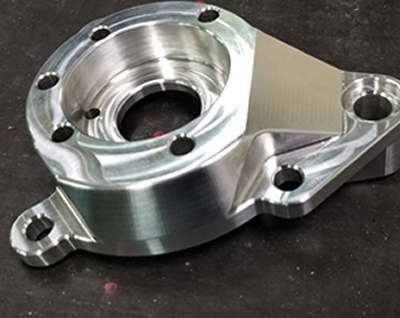

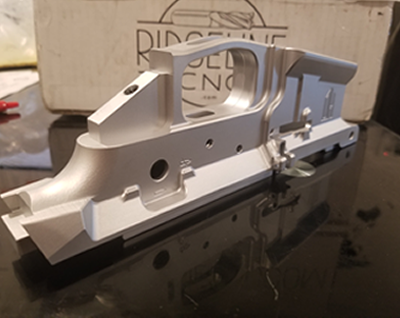

Simple. Fast. CNC Milling

At RidgelineCNC, we are fully prepared to assist you with all your machining requirements. Our array of CNC milling centers empowers us to fabricate components with both simple and intricate geometries, ensuring high-speed and precise results. Our primary objective is to provide a level of service that is unmatched anywhere else, catering to your unique needs with utmost dedication.