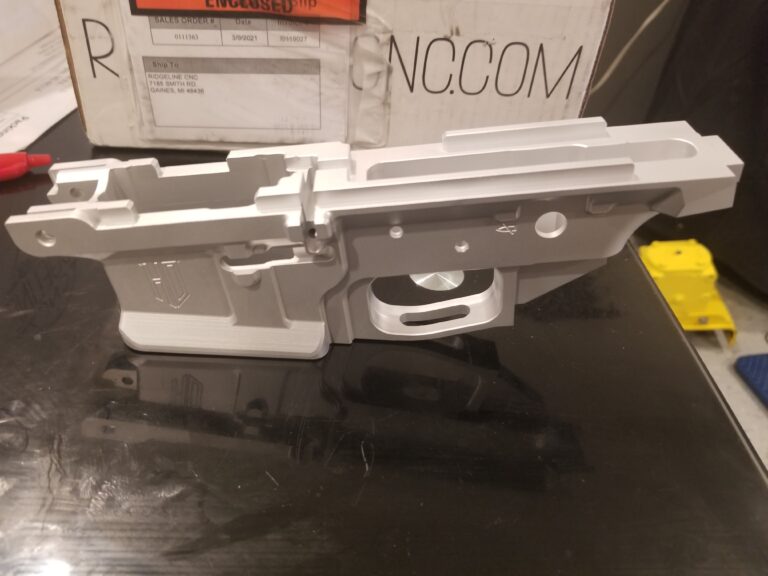

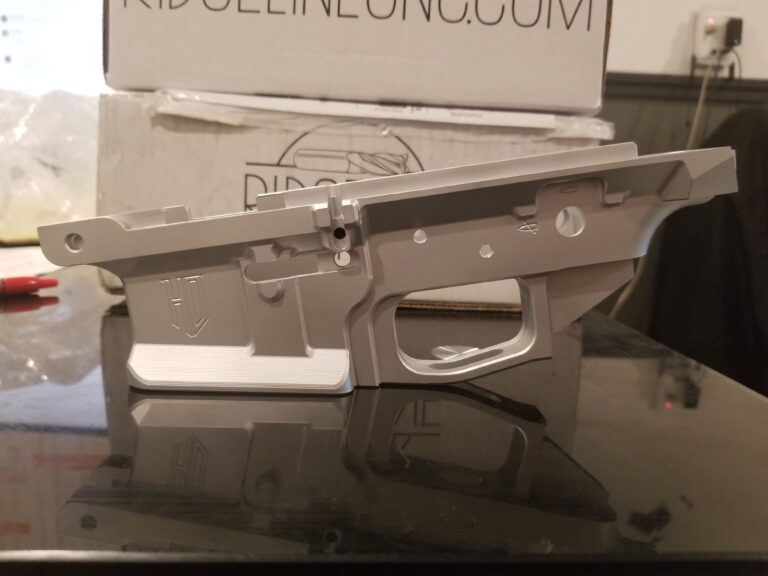

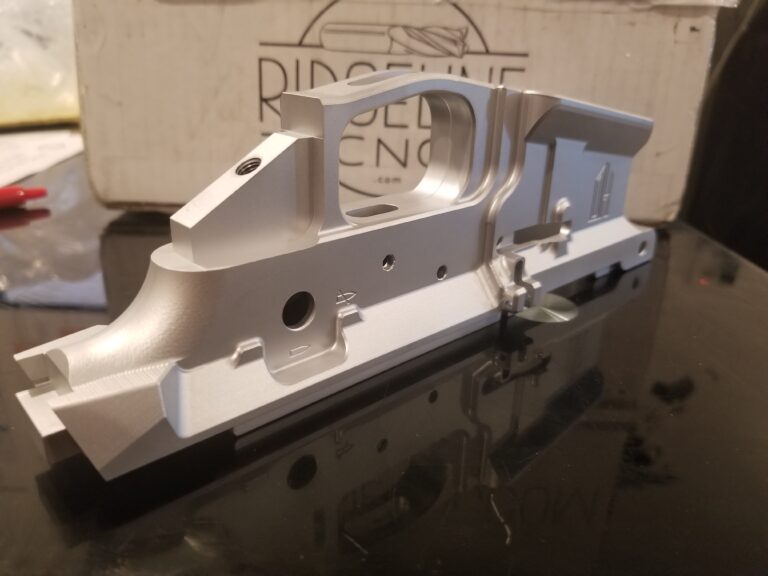

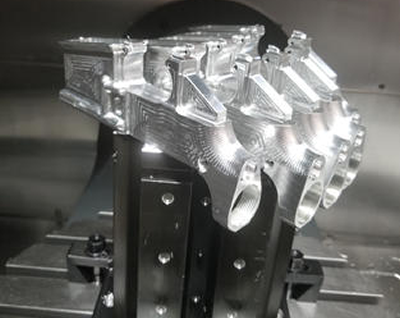

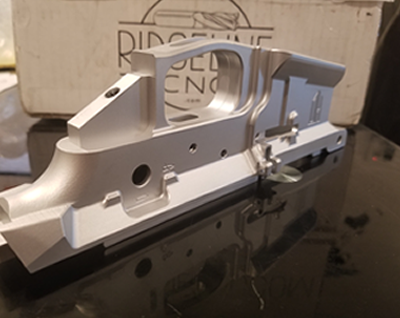

MODERN FIREARM COMPONENT MANUFACTURING

Quality, reasonably priced precision firearms machining parts with exceptional customer service.

Our clients have come to depend on our cutting-edge precision machine shop for machined firearm products, and we consistently meet their expectations. As a leading figure in the field of firearm machining, CNC machining, and firearm component manufacturing, we are continuously enhancing our processes among other machine companies.